What is a Resistance Temperature Detector (RTD)?

-

By

ATP Instrumentation

By

ATP Instrumentation - 4 Nov 2022

- 0 Comments

Welcome to the world of high accuracy temperature measurement. This article is aimed to give you, our valued ATP customers, a simplified overview of the how a Resistance Temperature Detector is designed and operates so you can customise and purchase your unit will full confidence, knowing you are getting exactly what you need. So out the door with all that Jargon, here is how they really work! Resistance Temperature Detectors (RTD) are a type of temperature sensor that utilities a resistor,

A resistor simply means, a device that has a resistance to electrical current passing through it

Temperature fluctuations alter the level of resistance within the resistor, which can then be correlated to a temperature reading.

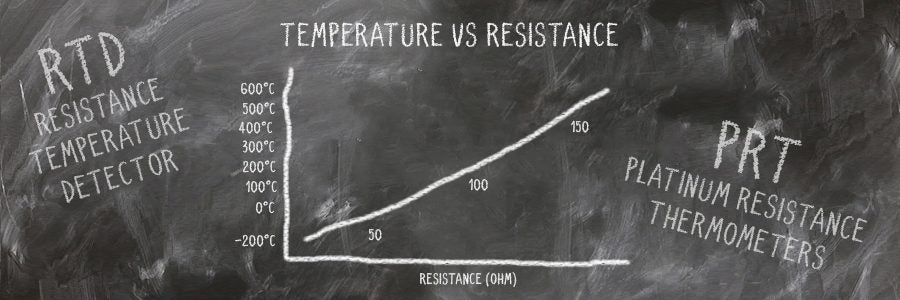

Platinum Resistance Thermometers (PRT)

The most common form of resistors used are constructed of platinum. Platinum has become the material of choice because it follows a very linear resistance to temperature relationship, in a repeatable manner over a large temperature range. In simple terms, this means that for every degree the temperature rises or falls, the resistance in the sensor changes by a very similar amount, it does this time and time again with very little variation and does so from very low to high temperatures. This produces what we call the temperature resistance curve, you can see it on the diagram below

Image supplied by http://www.instrumentationtoolbox.com

Pt100 vs PT1000

You may have heard of the most common RTD sensor, the Pt100. The letters Pt in a Pt100 sensor signifies the use of a platinum resistor. Pt100 sensors have a resistance of 100 ohms at 0°C. If, for example, the temperature rises to 1°C the resistance would change to 100.39 ohms. A Pt1000 is a more accurate version of the same type of sensor. The difference is that at 0° it has a resistance of 1000ohms. This higher resistance allows it to pick up on smaller changes to resistance. To expand on our previous examples, If the temperature rose to 1°C the resistance would change to 1003.90 ohms. This allows the Pt1000 a greater resolution than the Pt100. Bu which do you need? Is most applications you will find a Pt100 more than adequate for your needs. The “increased accuracy” of a Pt1000 can be matched with clever use of a wide range of custom probes that alters the overall accuracy and performance of your unit as a whole.

Who Uses RTD's?

The great thing about RTD’s is their versatility. Our own Pt100 has already begun replacing thermocouples in lower temperature (sub 400°C) industrial applications as it offers a much improved level of accuracy and response time. Importantly it is a cost effective upgrade as Class 2 (the cheaper end) of the available probes are more than adequate for most industrial applications. On the other side of the coin the Pt100 sensor is taking the laboratory industry by storm. With the introduction of directives to remove high accuracy mercury thermometers from use within the UK a viable alternative is needed. High accuracy 1/10 DIN probes along with UKAS certification allow exceptionally precise measurement. Weather using the device to calibrate a whole production lines of thermometers or utilising it in high precision machinery/equipment. There really no better or accurate device in a laboratory environment.

Next Steps...

Your next step, check out our guide Pt100 Accuracy and Probe Classification for details on how to calculate the accuracy of your device, and information on probe classification. Alternatively you could take a look at our Guide to Picking your Pt100 Probe to see the types of probes available, your options for customisation and how to get your FREE custom quotation. Although it is aimed at helping customers wanting to purchase our Pt100 Thermometer, it also has some great insights for those wanting to learn more about Pt100 sensor options.